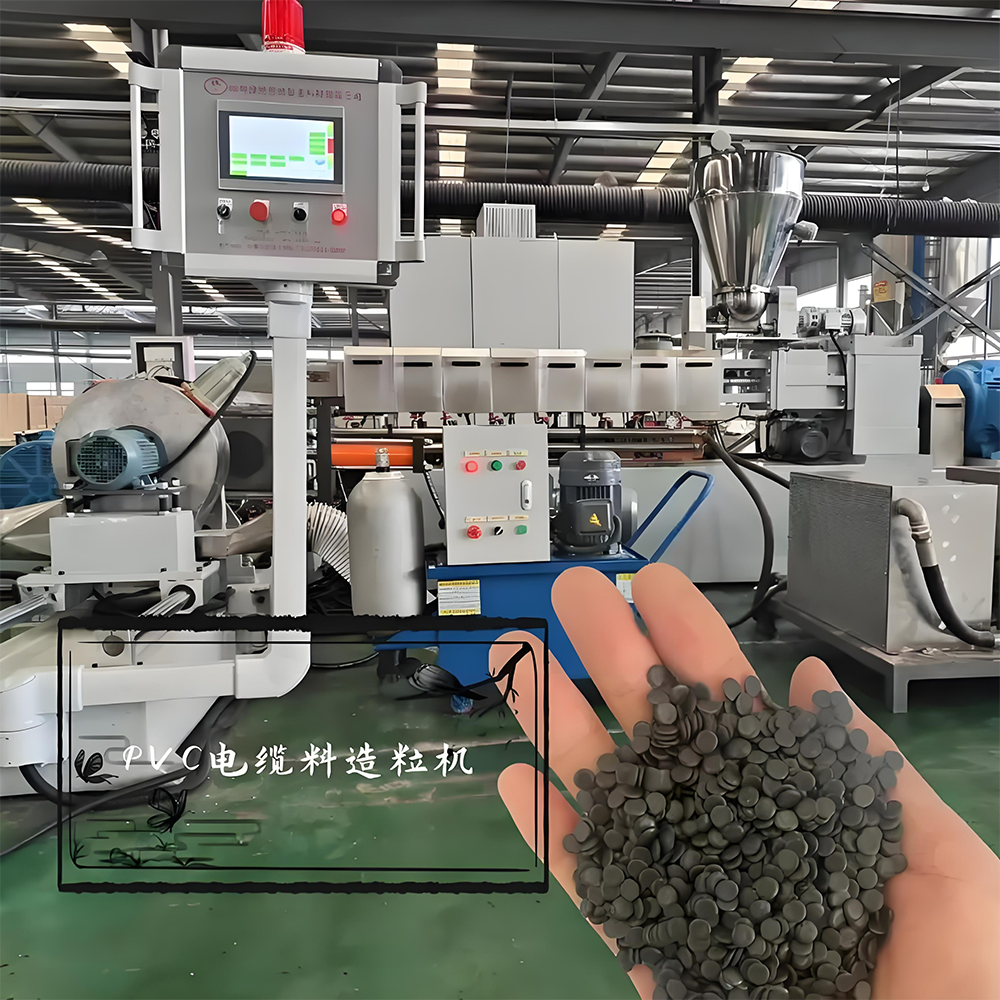

Polyvinylchloride (PVC)

Applications for most industrials

especially electronic devices, and

cable assemblies

Polyvinylchloride (PVC)

Applications for most industrials

especially electronic devices, and

cable assemblies

Polyurethane (PU)

Used for harsh running environments

that require critical flexibility,

abrasion resistance...

Polyurethane (PU)

Used for harsh running environments

that require critical flexibility,

abrasion resistance...

Thermoplastic elastomer (TPE)

Dirty, dangerous, and strict

temperatures solution for

automotive, military, medical fields

Thermoplastic elastomer (TPE)

Dirty, dangerous, and strict

temperatures solution for

automotive, military, medical fields

Polypropylene (PP)

Inner molded material for most

molding applications with cost

and product efficiency

Polypropylene (PP)

Inner molded material for most

molding applications with cost

and product efficiency

Multiple Materials for the Most Effective Applications

Wire extrusion by ourselves

The advantages of performing wire extrusion in-house include the following:

Cost and Efficiency

- Lower Production Costs: In-house wire extrusion allows for better control over material usage and production processes, reducing overall costs.

- Increased Productivity: By handling the extrusion process internally, companies can optimize production schedules and reduce downtime, leading to higher output.

Quality Control

- Consistent Quality: In-house extrusion enables continuous monitoring and control of the production process, ensuring that each wire meets the required standards.

- Immediate Defect Detection: Any defects or deviations can be identified and corrected immediately, preventing the production of substandard products.

Customization and Flexibility

- Tailored Solutions: Companies can customize wire dimensions, materials, and properties to meet specific application requirements.

- Quick Adaptation: In-house capabilities allow for rapid adjustments to production parameters, such as changing material types or modifying wire specifications.

Material and Process Optimization

- Optimized Material Use: In-house extrusion ensures precise control over material consumption, reducing waste.

- Enhanced Process Control: Advanced monitoring systems can be integrated to maintain consistent temperature, pressure, and speed, resulting in high-quality wires.

Strategic Advantages

- Reduced Dependency: By performing extrusion in-house, companies can reduce reliance on external suppliers, ensuring a steady supply of high-quality wires.

- Competitive Edge: The ability to produce custom wires efficiently can provide a competitive advantage in the market.

Eco-Friendly Materials

All incoming raw materials are rigorously tested to ensure 100% compliance with our HSF (Hazardous Substance Free) regulations. All finished products are certified to fully comply with the HSF standard.